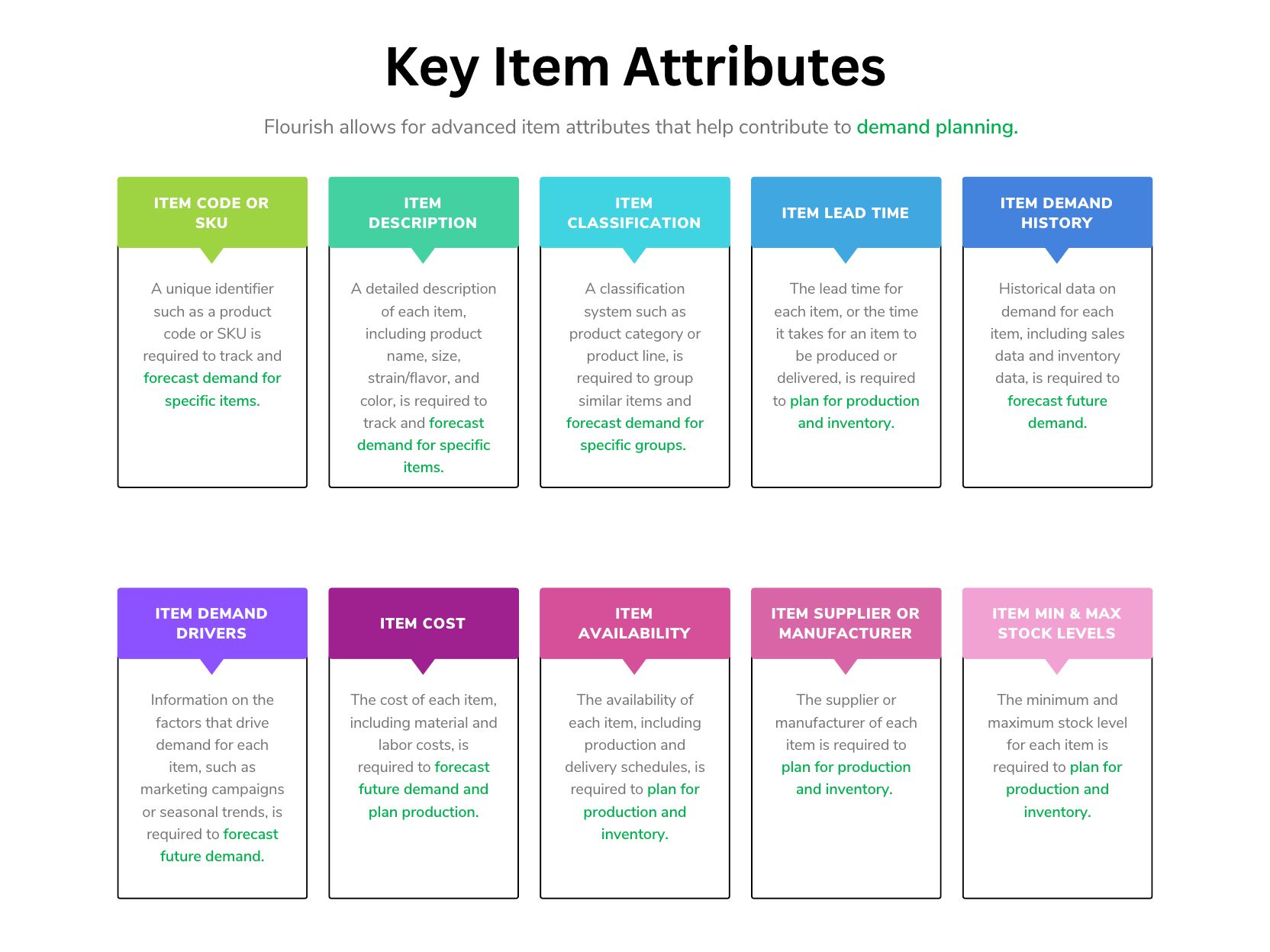

Demand planning is the process of forecasting the future demand for a company's products or services. It involves analyzing historical data, market trends, and consumer behavior to make predictions about future demand. The goal of demand planning is to ensure that your organization has the right products, in the right quantities, at the right time to meet customer demand.

How can cannabis processors, producers, distributors, and retailers leverage demand planning in their operations, and what tools are available that meet this industry's complex supply and demand criteria? Let's dig a bit deeper.

Are Demand Planning and Production Planning the same?

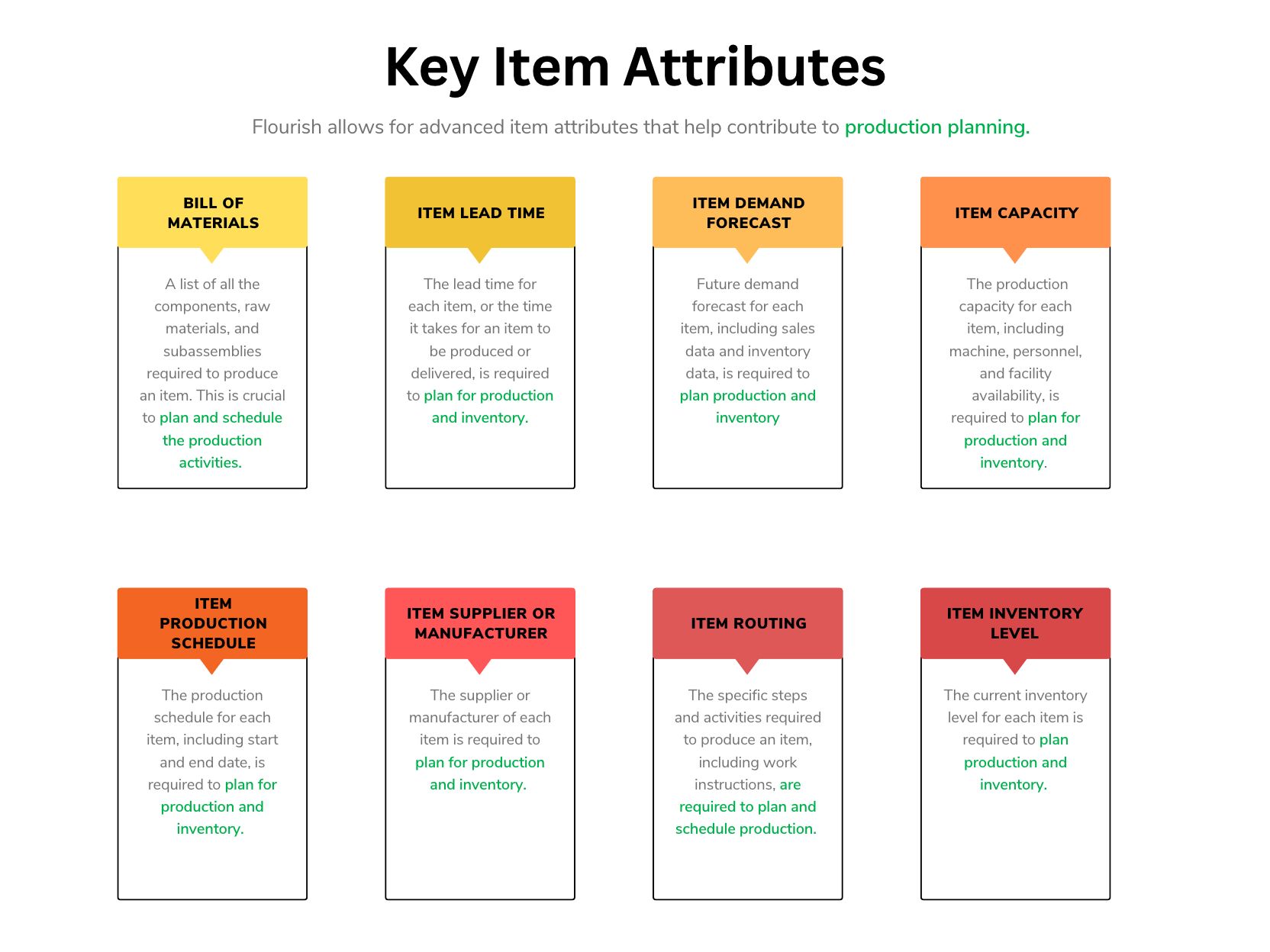

Not quite. Production planning determines how to best produce your products or services to meet demand. It involves determining the resources (people, materials, equipment) needed to produce a product or provide a service, when to produce it, and in what quantities. The goal of production planning is to ensure that you can produce products or services in a timely and efficient manner to meet customer demand.

Think of Demand planning and Production planning as a two-step process: demand planning ensures that your company has a clear understanding of customer demand, while production planning ensures that resources and processes are in place to meet that demand. Both are important for a company's overall supply chain management strategy.

What are some challenges the cannabis industry faces when implementing a demand planning solution?

Legal and regulatory environment: This is a heavily regulated industry - and laws and regulations vary by state, county, and even city. Regulations can also change on a whim, making it difficult to forecast and plan production and distribution.

Lack of historical data: Being a relatively new market, there is a lack of historical data that can be referenced for forecasting making it challenging to predict demand.

Rapidly changing consumer preferences + limited access to market research: We're all aware of how rapidly this industry is evolving and consumer trends frequently change and shift - from varied consumption methods such smoking, vaping, edibles, and topicals to cannabinoid-specific products like THC, CBD and now CBN. As a market that is still developing and changing, there are limited market research tools capable of adequately tracking consumer trends in a market that moves as fast as cannabis.

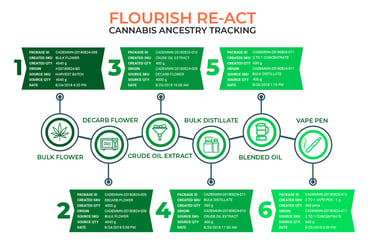

Complex supply chain: The cannabis industry supply chain is complex and involves multiple stages, from cultivation to processing, packaging, and distribution. This can make it difficult to manage inventory and plan for demand.

How can an inventory management system like Flourish support demand planning?

Flourish can play a crucial role in supporting demand planning. Our platform was developed by a team of seasoned supply chain professionals who recognize the significance of accurate demand forecasting. That's why Flourish is designed to deliver the insights and transparency needed to make informed decisions about inventory levels, lower costs, and enhance customer satisfaction, this includes:

Accurate inventory data: Track inventory levels, stockouts, and reorder points, providing accurate data to support demand forecasting and replenishment planning.

Real-time visibility: Gain real-time visibility into inventory levels, enabling you to respond quickly to changes in demand and avoid stockouts.

Automated replenishment: Automate the replenishment process, helping to ensure that inventory levels are maintained at optimal levels.

Inventory forecasting: Forecasting based on sales history and other data, giving insights on how much inventory to hold in the future.

Track supplier lead times: Track supplier lead times, which is crucial for replenishment planning.

Integration with demand planning tools: Integrations with demand planning tools to provide a more accurate demand forecast, which in turn improves your inventory management.

Track inventory costs: Track inventory costs, providing insights on the cost of holding inventory and helping to optimize inventory levels.

How to Implement a Demand Planning Tool

Before implementing a new demand planning tool, it's important to evaluate your specific needs and choose a tool that best fits those requirements. To prepare for adopting a demand planning tool, take the following steps.

- Define your demand planning objectives: Determine what you want to achieve with a demand planning tool, such as improving forecasting accuracy, automating the demand planning process, or gaining better visibility into demand patterns.

- Assess your current demand planning process: Evaluate your current demand planning process, including how data is collected, how forecasts are generated, and how demand planning decisions are made.

- Identify data requirements: Determine what data is needed to support your demand planning objectives and assess the availability and quality of that data.

- Evaluate potential solutions: Research different demand planning tools and evaluate their capabilities, pricing, and customer support.

- Develop a deployment plan: Create a plan for deploying the chosen demand planning tool, including timelines, resource allocation, and any necessary training and support.

- Test and validate the solution: Test the chosen demand planning tool to ensure it meets your requirements and validate that it improves the demand planning process.

- Monitor and improve: Monitor the performance of the demand planning tool and continuously look for ways to improve it.

- Communicate the changes and best practices to all stakeholders: As the demand planning process will be changed, it is important to communicate the changes, best practices and the reasons for them to all stakeholders.

Below are some popular demand planning tools for the SMB market:

- ForecastX by John Galt Solutions

- DemandWorks by ToolsGroup

- Blue Ridge Demand Planning

- SAP IBP (Integrated Business Planning)

- Demand Solutions by DSI

- Anaplan

- SmartForecasts

- JDA Demand

- Kinaxis RapidResponse